Meta Description

Planning a bulk artificial-plant order? Learn five essential checks—materials, supplier capacity, packaging, landed cost (with DDP tips), and warranty support—to avoid hidden expenses and protect margins.

Quick Summary

Before confirming a bulk order of artificial plants, procurement teams should check:

- Materials & UV resistance

- Supplier capacity & certifications

- Packaging & transit protection

- Full landed cost, not just unit price

- After-sales warranty & reorder speed

This guide explains each point with examples and questions to ask your supplier.

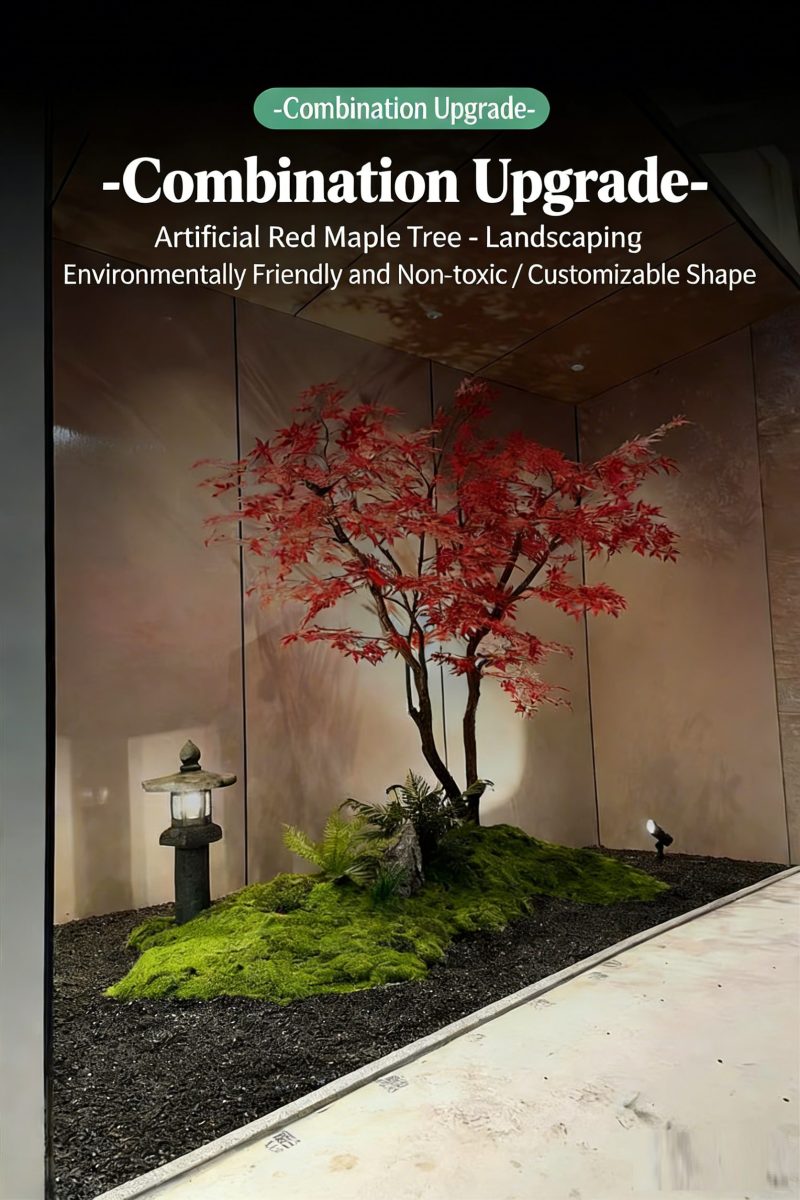

1. Materials and Realistic Appearance

The choice of material directly affects durability and how natural the plants look.

| Material | Strengths | Weaknesses | Typical Use |

|---|---|---|---|

| PE (Polyethylene) | Affordable, light, easy to mass-produce | Lower heat resistance | Indoor wall panels, large installations |

| PU (Polyurethane) | Soft touch, lifelike finish | Higher cost | Premium hotel lobbies, close-up décor |

| Silk Fabric | Vivid colors, elegant texture | Attracts dust, needs stronger protection | Floral arrangements, centerpieces |

For outdoor or sunlit areas, always ask if UV-resistant coating is applied. Without it, fading may occur in under a year.

👉 Example: A resort in Southeast Asia had to replace a vertical green wall after just 12 months due to fading. Choosing UV-rated foliage from the start would have avoided the extra expense.

(Source: AIPH – International Association of Horticultural Producers, 2024 Industry Brief link)

2. Supplier Capacity and Compliance

Reliability often matters more than a small price gap. Key checks include:

- MOQ (Minimum Order Quantity): Most factories set 100–500 units per style.

- Lead Time: Standard orders take 15–25 days; customized designs may exceed 40.

- Certifications:

- Europe: REACH or RoHS compliance

- U.S.: Fire-retardant standards such as UL94

Factories with proven annual capacity and international certifications are usually more stable partners than small workshops.

3. Packaging and Logistics Protection

Artificial plants do not spoil, but weak packaging leads to bent stems or unsellable stock.

- Container planning: Large plants are often shipped in parts to avoid deformation.

- Protective materials: Foam, cardboard frames, and stretch wrap prevent transit damage.

- Sustainable packaging: Recyclable cartons are increasingly requested in Europe and can improve brand image.

👉 Tip: A single shipment damaged in transit can wipe out freight savings. Packaging is worth the investment.

4. Total Cost: Beyond the Unit Price

Unit cost is only one part of the real expense. Always calculate the landed cost, which includes:

- Factory price

- Freight (ocean or air)

- Import duties and customs clearance

- Local delivery to warehouse

Some suppliers lower ex-factory prices but raise freight charges. To avoid surprises, request a DDP (Delivered Duty Paid) quote.

👉 Example: Freightos notes that landed cost can increase total expenses by 15–20% when duties and local delivery are ignored.

(Source: Freightos – Landed Cost Guide)

5. After-Sales Support and Long-Term Value

For distributors managing continuous demand, supplier support matters as much as the first shipment.

- Warranty: Reliable suppliers often provide 12–24 months against fading or defects.

- Reordering speed: Essential for seasonal or repeat projects.

- Customization: Private-label packaging or logo branding builds stronger resale value.

Choosing a partner who supports your growth—not just a low quote—secures profitability in the long run.

Final Takeaway

Bulk ordering artificial plants is more than comparing price lists. Careful checks on materials, supplier reliability, packaging, landed costs, and warranty services protect margins and build long-term partnerships.

Attention to these five details is what turns a one-time order into a sustainable wholesale business.